Non - Ferrous Centrifugal Castings, Castings In Copper Alloy, Castings For Boiler Machinery, Castings For Chemical Industries, Manufacturer, Pune, India

Casting calls for a great level of expertise, supreme technical knowhow, state-of-the-art technology, and robust engineering capabilities – four things we pride ourselves in being equipped with. We are your go-to doyens for all-things-brass-and-bronze. Our forte lies in producing non-ferrous centrifugal castings and our professionally-managed manufacturing unit in Pune enables us to craft and deliver all types of brasses and bronzes of the highest quality.

Who we are?

Spin-N-Cast is a partnership firm based in Pune, Maharashtra, with a strong team of experienced professionals including trained engineers, expert quality controllers, and capable sales pros.

The enterprise, founded in 1988, now flaunts a state-of-the-art production facility that has a total built-up area of 16,000 sq. ft. and is stacked with all the essential apparatus, thus making it an all-encompassing manufacturing unit.

The company has all the prerequisite authorizations, with a valid import-export license, and is registered with all the required government departments like the State and Central Sales Tax, SSI, NSIC, Ministry of Defense, Central Excise, etc.

What we do?

We take pride in being amongst the most sought-after engineering company in the state of Maharashtra when it comes to manufacturing brasses and bronzes of all kinds. Adroit at using the centrifugal casting (rotocasting) method, we have been delivering top notch axi-symmetrical castings to over 200 reputed companies for more than 27 years.

Our manufactured pieces are delivered to the clients in proof-machined or finish-machine condition, depending on their requirements, specifications, and drawings.

Combining methodical processes with new-age technology and skilled human resources, we serve a wide array of customers from diverse industries with products that are tailored to meet their specific needs.

Mission/Vission

- To be the enabler of stronger, solider and steadfast end products (in India and abroad) by delivering topnotch casting solutions across industries.

- To grow the business with the same integrity and honesty with which we craft our products.

- To constantly exceed our customers expectations in terms of quality, cost, delivery and time.

- To set a benchmark in the casting industry by achieving high standards of manufacturing through continuous innovation and adoption of new technology blended together with our traditional values and the core principles of engineering.

Mission Statement

To be a leader in producing non ferrous centrifugally cast components globally. Our mission is to enable businesses throughout the world to realize their full potential. We consider our mission statement as a commitment to our customers and deliver on that commitment by constant innovation, rapid development to create well engineered products.

Quality Policy

To ensure customer satisfaction through adopting continual improvement in processes, products, quality and the effectiveness of quality management systems and pursue growth by focusing on excellence on organizational and individual level.

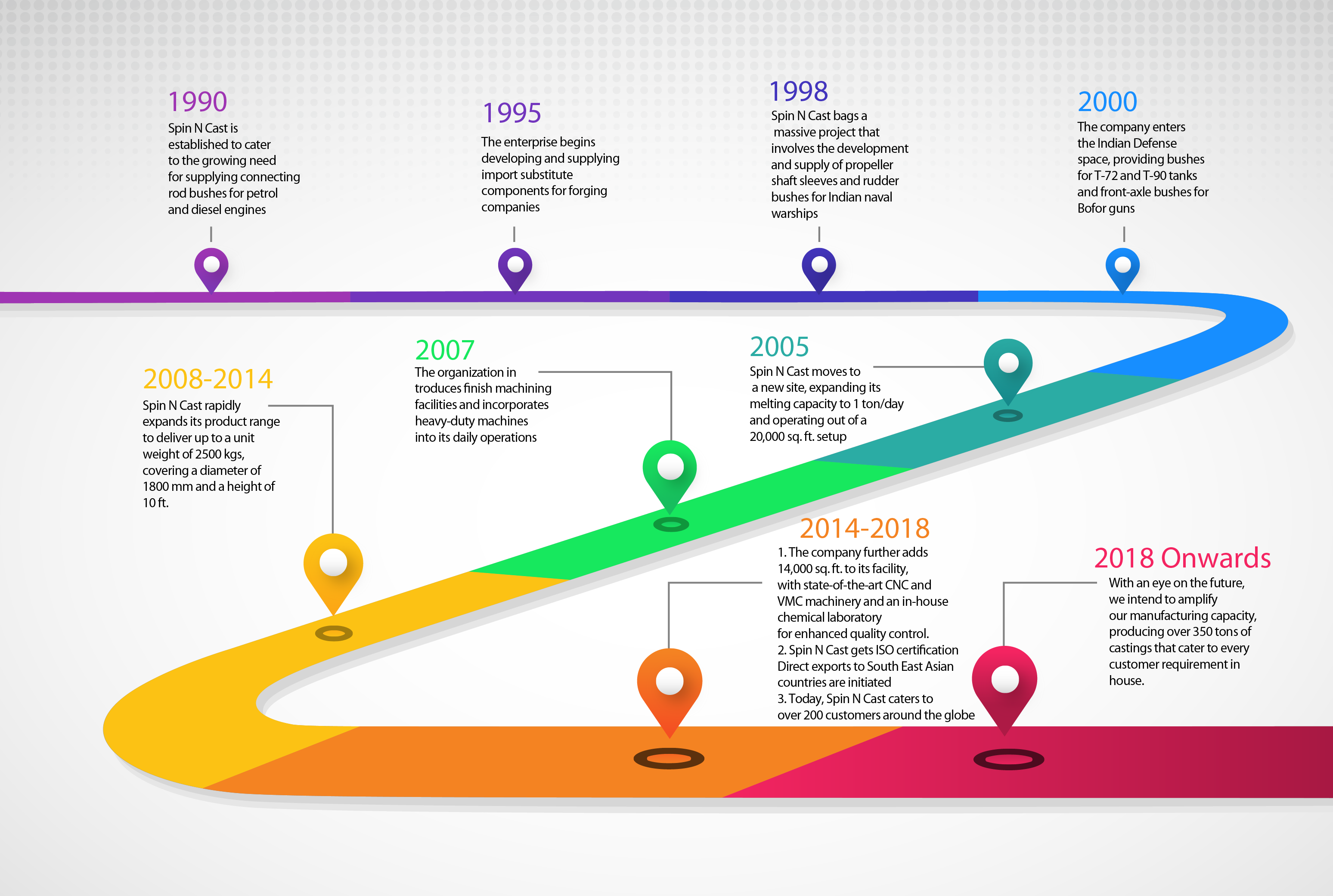

Company Timeline

Increase in pouring tonnage (annually) over the years:

1990-95 - 100 tons

1995-2000 - 150 tons

2000-2005 - 180 tons

2005-2015 - 300 tons

2015-2018 - 325 tons

2018-2020 - Projection of over 400 tons