Non - Ferrous Centrifugal Castings, Castings In Copper Alloy, Castings For Boiler Machinery, Castings For Chemical Industries, Manufacturer, Supplier, Pune, Maharashtra, India

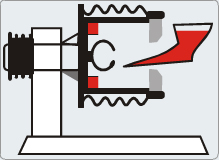

Often referred to as close grain casting ', centrifugal casting is widely acknowledged as the most suitable foundry process for producing heavy-duty (and high-reliability) components.

It is significantly different from other metal casting processes. Here, molten metal is centrifugally poured into a rotating/revolving (in the direction of the interior mould wall) for it to cool down and solidify. The heat extractions by metallic moulds and high compressive pressure exerted by the centrifugal force make this possible.

Variables like the angle of the axis of rotation, speed of rotation and metal pouring rate can be adjusted according to the alloy at hand and the size/shape being cast.

Why Centrifugal Casting?

One of the major reasons why centrifugal is the preferred method is that the end product has a fine grain micro structure and is free from porosity. Other key benefits include:

- High wear quality

- Perfect soundness fetching high mechanical properties

- Excellent physical properties (high tensile, creep and fatigue strength) resulting in long-lasting castings

- Improved resistance to wear and tear

- Absolute pressure tightness

- Elimination of blow holes and inclusions before finish machining

- Lesser wastage of material, thanks to the low cast weight to finish weight ratio

- Substantial reduction of equipment downtime resulting in cost- and time-efficient production

Centrifugal v/s Sand/Static Casting

Centrifugal casting unarguably has an upper hand over sand/static casting since the end result achieved upholds over 30% more physical properties when compared to the latter.

Here 's a quick look at some prominent features that make centrifugal casting the favoured process the world over:

| Particulars | Centrifugal Casting | Sand/Static Casting |

| Micro structure | Dense & uniform | Spongy & uneven |

| Grain flow | Radial & uniform | Linear & non-uniform |

| Tensile strength | High | Low |

| Solidity | Uniform hardness | Low & non-uniform hardness |

| Impact loads | Can withstand high impact loads | Doesn 't sustain impact loads |

| Pattern | Not required | Required |

| Surface finish | Excellent | Poor |

| Micro porosity | Not present | Present |

| Lifespan | More | Less |